Laser Welding Machine Antifreeze Protection

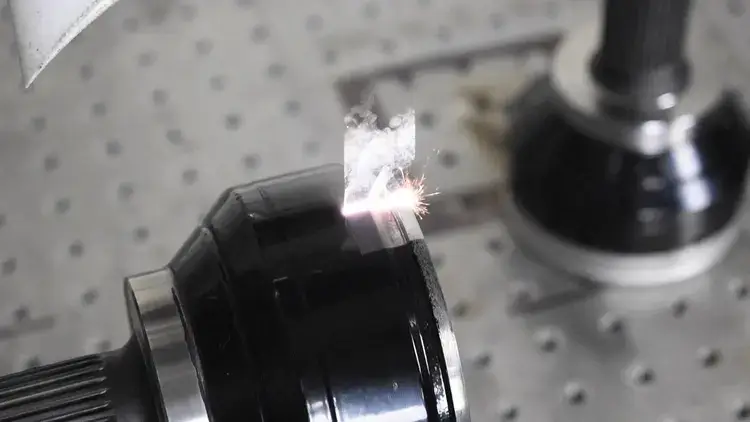

Laser Welding Machine Antifreeze Protection Why should we pay special attention to laser welding machines in winter? Most laser welding machines have a built-in chiller to cool the fiber laser and the handheld laser gun (aka handheld laser torch). As we all know, water freezes below 0°C (32°F). When water changes from liquid to solid, […]

Laser Welding Machine Antifreeze Protection Read More »