Industrial laser cutting machines are broadly categorized based on the processed products into flat steel laser cutters, tube laser cutters, structural steel laser cutters, and three-dimensional five-axis laser cutters for advanced manufacturing applications ans so on. Investing in a steel sheet laser cutting machine is a major decision for any metal fabrication business. Too often, buyers focus only on laser power or price, overlooking critical factors that determine long-term value, reliability, and productivity.

Why Power and Price Aren’t Enough when we choose laser cutter? While kW rating and cost are obvious considerations, they don’t reveal how the machine will perform after 5–10 years of continuous operation. For instance, two machines with the same 6 kW laser can have drastically different results—one may hold ±0.02 mm accuracy after years of production, while the other drifts within months due to structural weaknesses. Precision, uptime, and total cost of ownership (TCO) come from design details, system reliability, and operator-friendly features.

In this article, we go beyond the basics to highlight what really matters when evaluating sheet metal laser cutting machines.

Primary Keywords: steel sheet laser cutting machine, sheet metal laser cutter, metal laser cutter, CNC laser cutting machine.

1. Structural Stability and Precision

Accuracy in laser cutting is heavily reliant on the machine’s foundation. Think of it like building a house: if the foundation shifts, no amount of adjustments can fix the cracks. The stability of the laser cutter’s bed and its anchoring system directly influence its long-term precision and operational efficiency.

1.1 Robust Bed

A high-quality industrial laser cutting machine uses 12–16 mm welded steel plate structures that are carefully stress-relieved. This stress-relief process ensures that no hidden internal stress remains in the frame, which can lead to warping or distortion over time. The result is a bed that stays true for many years, providing consistent precision.

For example, a sheet metal laser cutter with a bed built to such standards can maintain tight tolerances even after years of high-speed operation. Conversely, machines that cut corners with thinner, untreated beds may appear cheaper initially, but the long-term costs can outweigh the savings. On the other hand, suppliers who neglect stress-relief may offer a 5% cost saving upfront, but this often leads to alignment issues and more frequent recalibration, which can cause higher downtime and more expensive repairs down the line.

1.2 Anchoring System

While a desktop flat sheet laser cutter might be easy to set up with simple disc feet, this setup lacks the necessary stability for high-precision cutting. Over time, the weight of the machine causes these feet to sink unevenly into the floor, gradually affecting the alignment. A more robust anchoring system that uses footplates and expansion bolts secures the machine firmly to the floor.

This ensures that the bed stays level and aligned, even after years of use. Such an anchoring system is crucial when cutting materials like thin stainless steel sheets. Even the smallest misalignment—just a 0.1 mm shift—can ruin entire batches, affecting product quality and increasing waste. By opting for a machine with a secure anchoring system, businesses can ensure the longevity and accuracy of their equipment, resulting in fewer operational disruptions and better cost-efficiency over time.

2. Efficiency and Ergonomics

While cutting speed is important, overall productivity depends significantly on operator comfort and workflow design. In a real-world setting, factors like ease of use, safety, and smooth transitions between tasks can dramatically impact the efficiency of a metal laser cutter. Machines that prioritize ergonomic design and streamline workflows ultimately lead to faster production times, lower labor costs, and higher output.

2.1 Ergonomics

Operator comfort plays a vital role in maintaining consistent productivity. For example, a working height of around 800 mm is optimal for reducing strain during loading and unloading, preventing fatigue, and improving speed. Workers in a factory handling heavy carbon steel sheets found a 20% increase in turnover speed when they switched from a 900 mm to an 800 mm work table.

This small adjustment significantly reduced physical strain and allowed operators to work more efficiently, resulting in faster job completion and better overall productivity. In contrast, machines with higher worktable heights may increase the risk of repetitive stress injuries, leading to slower workflows and increased healthcare costs.

2.2 Dual Pallet Exchange

Sheet metal laser cutters equipped with a dual pallet exchange system offer a game-changing advantage by allowing the operator to load one pallet while the machine is actively cutting with the other. This design minimizes downtime significantly, as the transition between jobs is almost instantaneous.

For instance, a 10-second pallet swap system can save hours of manual labor each week. This may not seem like much, but over the course of a year, it can result in thousands of extra parts cut, which directly translates to higher revenue and better utilization of the equipment. Businesses that invest in this system often report a considerable improvement in throughput and reduced idle time, enhancing the overall productivity of their operation.

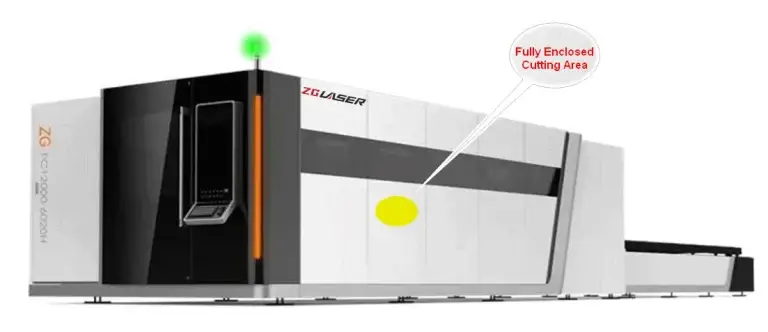

2.3 Enclosed Safety Design

An industrial metal laser cutter that includes an enclosed design for cables and moving parts ensures a safer and more efficient working environment. Exposed cables and other vulnerable components can be a significant risk in busy factory settings. Imagine the disruption and cost of repairing a laser cutter after an operator accidentally snags an exposed cable while handling sharp-edged aluminum sheets. In contrast, a machine with an enclosed design—featuring protected cabling and integrated tank chains—prevents this kind of damage, which can lead to costly repairs and extended downtime.

The investment in a fully enclosed machine often leads to greater long-term savings by preventing avoidable damages and minimizing workflow interruptions. Safety features like these contribute not only to better worker protection but also to the smooth operation of the machine, maintaining uptime and reducing the risk of accidents on the shop floor.

Generally,a manufacturer using a fiber laser cutting machine for stainless steel sheets with a dual pallet system was able to cut 35% more parts per shift compared to their previous setup.

3. Reliability of Core Systems

The laser source and control systems are the heart of any CNC laser cutting machine, and their performance is directly tied to the stability of the machine’s operating conditions. Even the most powerful laser cannot deliver consistent, high-quality results if the systems that power it are not maintained properly or are subject to fluctuating environmental conditions. The longevity and reliability of these core systems are essential for maximizing uptime and reducing maintenance costs, ensuring that the machine can operate at full capacity for years to come.

3.1 Climate Control

High-end machines come with integrated climate control systems, such as built-in air conditioning and dehumidifiers, designed to regulate the internal environment of the machine. This is especially important in humid or fluctuating climates, where excessive moisture can lead to condensation inside the laser cutting machine’s cabinet. Condensation can wreak havoc on delicate electronics, causing short circuits or misalignments that reduce laser performance.

By maintaining a stable temperature and humidity level, climate control systems ensure that the laser source operates optimally, delivering consistent cutting performance over time. For instance, in a humid climate, a machine without climate control would experience issues like lens fogging or electrical system failures, resulting in increased downtime and costly repairs. With climate control, however, the machine runs smoothly and efficiently, eliminating the need for a separate, costly air-conditioned room and keeping operational costs low while enhancing reliability.

3.2 Dust Extraction

A fiber laser cutting machine produces a significant amount of smoke and particulate matter during the cutting process. If not adequately extracted, this can interfere with the laser’s sensors and optics, compromising both cutting quality and the overall lifespan of the machine. To prevent this, high-quality machines are equipped with zoned extraction systems that match fan power to the size of the cutting area. These systems ensure that smoke and debris are extracted efficiently, preventing contamination of the lens and other delicate components.

On budget machines, the extraction system is often inadequate, leading to lens contamination, which requires frequent replacements—each costing hundreds of dollars. Additionally, poor dust extraction can lead to sensor malfunctions and a buildup of debris around critical components, causing the machine to lose precision and efficiency. Investing in a proper dust extraction system significantly extends the life of both the laser optics and the machine itself, minimizing maintenance costs and ensuring high-quality, reliable cutting for years.

4. Safety and Thermal Protection

Safety is not merely a regulatory requirement—it is a critical investment in the overall productivity, longevity, and well-being of both the operator and the equipment. In high-stakes industries like metal fabrication, where precision and safety go hand-in-hand, ensuring robust safety measures can prevent costly accidents and downtime. Integrating effective safety and thermal protection systems into a metal laser cutter not only safeguards employees but also enhances machine performance and ensures regulatory compliance.

4.1 Enclosures

A CNC laser cutting machine with a fully enclosed cutting area offers significant safety benefits. Enclosures act as physical barriers, shielding operators from the harmful effects of sparks, fumes, and flying debris generated during the cutting process. The presence of a closed environment also prevents direct exposure to high-powered laser beams, which can be harmful to the eyes. Moreover, the enclosure helps reduce noise levels, creating a safer and more comfortable working environment.

Beyond operational safety, enclosed systems are often required to meet international safety standards (such as CE and UL certifications). Compliance with these standards not only enhances safety but also ensures that the company meets legal requirements, avoiding penalties or shutdowns. For example, in a factory setting, machines with exposed cutting areas may expose workers to health hazards like respiratory issues from fumes or injuries from moving parts, while fully enclosed designs mitigate these risks, improving both operator safety and machine compliance.

4.2 Thermal Safeguards

High-power fiber laser cutting machines (especially those rated 8 kW and above) generate an immense amount of heat during operation. Prolonged exposure to such heat without proper shielding can cause permanent damage to critical components like the machine bed, which can deform and lose precision over time. For instance, a fabricator cutting long, high-volume 12 mm steel sheets found that their machine bed was gradually warping due to the continuous heat generated from extended cutting runs. This warping led to significant accuracy loss, ultimately affecting production quality.

Machines equipped with integrated thermal protection systems are designed to manage this heat and prevent long-term damage. By dispersing heat evenly across the machine and protecting the bed, these systems maintain precision throughout long runs. As a result, the machine remains stable, and production output remains consistent. The absence of thermal protection not only affects the machine’s longevity but also directly impacts the quality of cuts, leading to inefficiency and higher operational costs.

5. Total Cost of Ownership (TCO)

When evaluating laser cutting equipment, focusing solely on the initial price tag can be misleading. Total Cost of Ownership (TCO) offers a more comprehensive perspective, taking into account factors like downtime, maintenance, and lifespan. While a cheaper machine might save money upfront, it can incur significant hidden costs over time, such as increased downtime, higher maintenance needs, and shorter lifespan. In contrast, an industrial-grade metal laser cutter that may seem expensive initially often proves to be a more economical choice in the long run, delivering better reliability, reduced maintenance costs, and increased productivity.

5.1 Lower Downtime

Unplanned downtime is one of the most significant contributors to operational inefficiency and lost revenue. Every hour a machine is idle not only costs labor but also impacts production schedules, potentially missing critical delivery deadlines. For example, a factory that experiences frequent stoppages due to machine malfunctions may face delays in fulfilling customer orders, leading to dissatisfaction and lost business.

Industrial-grade machines, built with more reliable components and better thermal management, are engineered to minimize these risks. With advanced systems like climate control and efficient dust extraction, these machines maintain stable performance over longer periods, reducing the likelihood of system failures. As a result, downtime is minimized, ensuring smoother operations and timely deliveries. A cheaper machine, while initially less expensive, often incurs higher downtime costs because of its inferior build quality, leading to more frequent breakdowns and greater productivity losses over time.

5.2 Longer Lifespan

The longevity of the machine is a key factor in TCO, especially when looking at the potential for long-term use. High-end industrial metal laser cutters are designed with durability in mind, incorporating stress-relieved beds, climate control, and reliable cooling systems to ensure smooth operation over an extended period. These machines are engineered to last 10 to 20 years or more with minimal performance degradation.

In contrast, low-cost alternatives, which often lack robust features like climate control or high-quality components, may need to be replaced in just half that time. For example, a fiber laser cutting machine for stainless steel sheets that doesn’t have proper thermal protection or climate control may experience warping and mechanical failures much sooner, shortening its useful life. While you might spend more upfront on a high-quality machine, the lower frequency of replacement and repairs results in substantial savings in the long run.

5.3 Reduced Maintenance Costs

Regular maintenance can significantly affect the total cost of ownership. Industrial-grade machines are built with features such as stronger dust extraction systems and stable temperature environments, which help protect critical components like lenses, optics, and linear rails from premature wear and tear. By preventing dust buildup and temperature fluctuations, these machines extend the life of vital parts, reducing the frequency of costly repairs and part replacements. For instance, a metal laser cutter equipped with a high-quality dust extraction system ensures that smoke and debris are efficiently removed, protecting delicate components like lenses from contamination. This contrasts with budget machines that often lack these features, resulting in higher maintenance costs as lenses and optics require frequent cleaning or replacement.

Over time, the savings on maintenance costs alone can make a significant impact on the TCO, proving that a more expensive, high-quality machine often offers greater value over its lifetime.

Let me calculate 10-Year TCO Breakdown

- Capital Cost: 25%

- Energy & Gas: 30%

- Maintenance: 20%

- Downtime/Labor: 15%

- Other: 10%

Example: Two manufacturers invest in similar power machines—one an industrial metal laser cutter, the other a budget option. After 5 years, the budget machine has incurred 3× higher downtime costs and 2× maintenance costs, wiping out any savings from the initial lower price.

Conclusion: Smarter Selection for Lasting Value

When approaching steel laser cutting machine selection, buyers should think beyond watts and euros. The right choice ensures:

- Precision for years, not months.

- Higher utilization thanks to ergonomic and workflow-friendly design.

- Long-term savings through reduced downtime and maintenance.

Whether you are choosing a large-scale system or a desktop flat sheet laser cutter for prototyping, the same principles apply: prioritize structure, system reliability, and safety over short-term savings. Businesses ready to scale should explore suppliers where they can buy steel laser cutting machine online with transparent specifications and proven service records.

Choosing a sheet metal laser cutter is not just about today’s performance—it’s about future-proofing your production line for efficiency and profitability.

FAQs

Q1: What should I look for when buying a steel sheet laser cutting machine?

A: Focus on bed stability, anchoring, climate control, and maintenance support. These factors ensure precision over the long term.

Q2: How do dual pallet exchange systems improve productivity?

A: They allow loading while cutting continues, reducing downtime by up to 40% and significantly increasing annual output.

Q3: Why is climate control important in sheet metal laser cutting machines?

A: It prevents condensation and overheating, protecting laser sources and electronics from costly failures.

Q4: What is the expected accuracy lifespan of an industrial metal laser cutter?

A: With proper installation and anchoring, industrial machines maintain ±0.02 mm/m accuracy for more than 10 years.