The Ultimate Guide for Laser Welding Machine(2022)

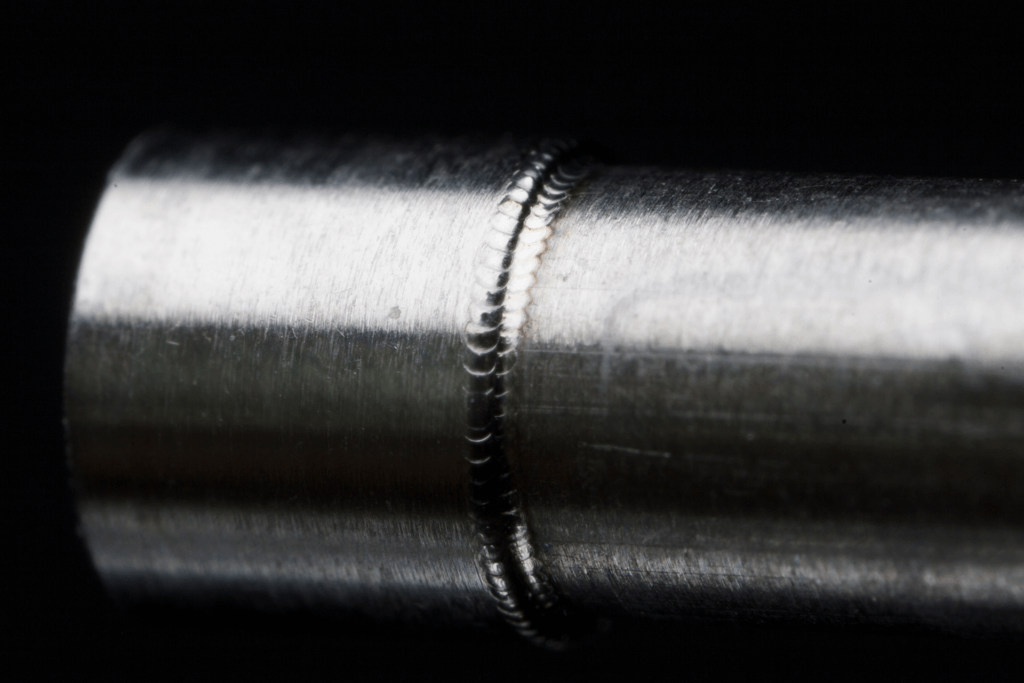

What is a Laser Welding Machine? A laser welding machine is a machine that uses a high-energy pulsed laser or CW lasers to irradiate a workpiece for welding purposes. It can regulate the energy of the pulsed laser by setting different laser frequencies and pulse widths to weld the workpiece accurately. Types of Laser Welding […]

The Ultimate Guide for Laser Welding Machine(2022) Read More »