Laser cleanning technology, especially for laser paint stripping for wood, is revolutionizing how we remove paint and coatings from wooden surfaces. This method has gained popularity due to its precision, eco-friendliness, and efficiency, particularly in laser furniture stripping and laser stripping wood applications. In this article, we will explore the principles, advantages, disadvantages, and comparison of laser stripping machines versus traditional paint removal techniques.

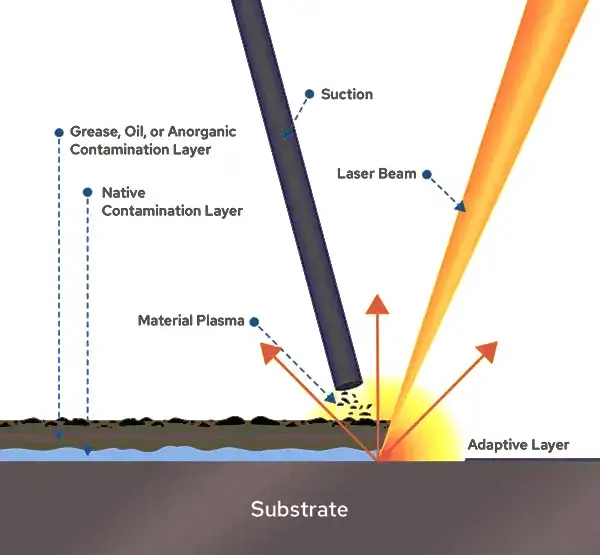

The Basic Principle of Laser Cleaner

Laser cleaning works by directing high-intensity laser beams at the surface of the wood. The laser light is absorbed by the paint or varnish, causing it to heat up rapidly and eventually break free from the wood. The high temperatures cause the paint to evaporate or flake off, while the underlying wood remains untouched, thanks to the precision of the laser stripping tool. The laser to remove varnish from wood process is highly controlled, allowing for different power settings to ensure that only the coating is affected, not the wood underneath.

Advantages of Using Laser to Remove Paint from Wood

Precision and Control

Laser stripper for wood offers precise control over the amount of energy used, allowing for targeted paint removal without damaging the wood. This is especially beneficial when stripping delicate furniture or intricate wooden carvings. Laser stripping machine for wood can even handle multi-layered paint without affecting the wood’s integrity.Eco-Friendly

Unlike traditional chemical methods, such as using solvents or paint strippers, laser stripping paint is environmentally friendly. There are no chemicals involved in the process, and laser paint strippers produce no harmful waste, making this a sustainable solution for furniture stripping laser operations.Minimal Wear and Tear

The laser sander for wood can help smooth the surface as it removes paint, providing a fine finish without scratches or gouges. This is particularly useful for high-end wooden furniture and antiques where preserving the surface texture is critical.Portable and Versatile

Many laser stripping machines are portable, offering ease of use in various locations. This makes them ideal for jobs that require mobility, such as stripping paint from old furniture or in-house restoration projects. Portable laser paint removal allows for flexibility when working with large items or difficult-to-reach areas.Time-Saving and Efficient

Using a laser stripper for large-scale projects is much faster compared to traditional methods like sanding or scraping. Laser paint stripping tools can efficiently remove paint in a fraction of the time, speeding up the overall project and reducing labor costs.

Disadvantages of Laser Cleaning

- High Initial Cost

While laser paint strippers provide numerous benefits, the cost of purchasing a laser stripping machine can be high, especially for smaller businesses or DIY enthusiasts. However, this cost can be justified over time with the efficiency and precision that laser technology provides. - Requires Skilled Operation

Operating a wood laser stripper requires a certain level of expertise. The machine settings must be adjusted carefully to avoid overheating or damaging the wood, especially when dealing with delicate surfaces. Improper use of a laser stripping tool can lead to unwanted effects.

Comparing Laser Stripping to Other Paint Removal Methods

Chemical Stripping

Chemical stripping involves using a solvent or gel to break down paint and coatings. While it can be effective, it involves harsh chemicals that can be harmful to both the environment and the user. Cleanup is often cumbersome, and chemical residue can damage the wood if not properly removed. On the other hand, lazer paint remover works cleanly without any mess.

Mechanical Stripping

Mechanical methods, like sanding or scraping, can remove paint but may result in scratches, uneven surfaces, or damage to the wood. While affordable, these methods are time-consuming and labor-intensive. Laser wood stripping machine offers a cleaner, quicker solution with less risk of damage to the wood’s surface.

Heat-Based Stripping (Steam or Hot Air)

Another technique is heat paint removal,or thermal paint stripping, where heat softens the paint for scraping. While potentially effective, this method works slowly and might not be ideal for intricate wooden surfaces. Laser stripping, on the other hand, offers a faster and more efficient solution by eliminating paint without subjecting the surface to excessive heat.

The Effect of Different Laser Powers on Paint Removal Efficiency

Based on existing relevant research, different laser powers exhibit varying removal efficiencies for wood coatings at different coating thicknesses. Taking pine boards(20 cm x 20 cm) commonly used in furniture manufacturing and commercially available wood lacquers as examples, the relevant experimental results are as follows:

- Optimal Laser Power

For removing thin paint layers(0.1mm), lower power (30 W or 50 W) was sufficient for efficient removal. For medium thick layers(0.5mm), higher powers (70 W and 100 W) were required to achieve optimal efficiency without multiple passes. However, 100 W was found to be too high for delicate wood surfaces, resulting in undesirable substrate damage. - Paint Thickness Impact

Thicker paint layers required higher laser power to be removed effectively. Thin layers showed high efficiency at lower power levels, while thicker coatings benefited from increased power to remove more material in less time. - Surface Damage

At higher laser powers, there is a greater risk of substrate damage, particularly with delicate materials like wood. It is recommended to use laser stripping tools at the lowest effective power to avoid damaging the wood.

Based on the findings, it is recommended to use laser sander or laser cleanner for wood at moderate power settings (50 W to 70 W) for most applications to balance efficiency with substrate preservation, especially when working with laser furniture paint stripping and laser paint stripping for wood. In industrial cleaning applications where minor substrate damage is not a concern, higher power laser paint stripper are recommended to enhance cleaning efficiency.

In summary, laser paint removal technology offers numerous advantages when stripping paint from wood surfaces. Whether using laser sanders or laser paint stripper, this method achieves efficient, precise, and environmentally friendly results. This technology cleans surfaces without chemicals or abrasives, making it an ideal choice for high-quality furniture restoration (such as laser furniture paint removal projects). It also offers a safer, more efficient alternative to traditional paint removal processes, particularly for delicate high-end wood products and antique furniture restoration.

With the increasing availability of compact laser paint stripping equipment, DIY enthusiasts and small business owners now have access to this technology. Whether for furniture restoration or large-scale woodworking projects, our company offers a diverse range of laser paint removal equipment.

More Products

ZG-HC Handheld Laser Cleaning Machine

It is paired with a high power continuous laser for fast rust removal, and the unique red light targeting allows it to precisely clean the target material.

ZG-HCM Pulse Laser Cleaning Machine

The MOPA pulsed laser makes it possible to keep the bottom material intact when cleaning items and to remove paint, oil and oxide film in addition to rust.

ZG-HCM-100B Backpack Laser Cleanner

The comfortable back frame and lightweight construction allow longer working time. The mobile laser system is fully operational, even without on-site power, thanks to battery operation.

ZG-LC100 Laser Cleaning Machine

The ultra-compact housing is designed as a professional-grade laser cleaning and surface preparation system for small areas requiring fine cleaning, paint removal, and other surface preparation operations.